The Woburn Casement Range

The WOBURN casement is an elegant, well proportioned timber window system offering SIX opening alternatives from the same basic section, making it one of the most flexible packages on the market today.Tailor-made to suit any configuration, either single or double-glazed and coupled with our in-house design service, sections can be adapted to meet aesthetic requirements of listed buildings and properties within conservation areas where attention to existing detail is a requirement.

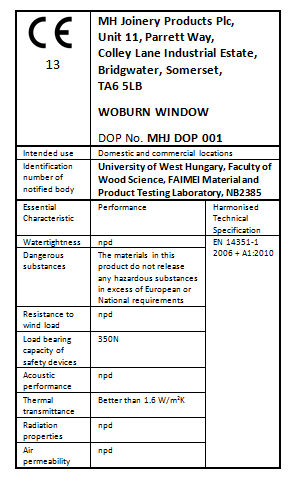

A Scandinavian influenced design, WOBURN windows have been tested to meet the most stringent British Standards.

Six opening alternatives

Six opening alternatives

The Woburn system offers six alternative openings, all from the same flush sash profile:1. Top hung canopy - an outward opening sash on heavy duty friction hinges.

2. Side hung sliding projection - an outward opening sash on heavy duty cantilever friction hinges with an opening angle of 90 degrees providing a wash space to permit safe internal cleaning of the outside glass face.

3/4. Side or top hung - an outward opening sash on modified butt hinges where ease of cleaning is not a requirement.

5. Side hung fully reversible - rotates through 180 degrees allowing the whole outside glass face to be made easily accessible for safe internal cleaning.

6. Top hung fully reversible - rotates through 180 degrees for safe and easy cleaning without intruding into the room. The hinge incorporates a safety restrictor.

Tailor-made Styles & Mouldings

Every window in the range is tailor made to order using our proven and tested sections. Any size, style and shape can be produced, within practical limitations, giving specifiers reasonable freedom of choice, proportion and size, suiting either refurbishment projects or new build developments.Materials and Construction

Windows are manufactured in quality European Redwood from PEFC certified forests or from environmentally sourced species of hardwood. Joints are formed using advanced machining methods and purpose designed tooling.Glazing

Woburn windows are supplied factory glazed in accordance with BS 6262. Variations including toughened, laminated, obscure glazing and gas filling are available upon request. Either single or double glazing can be supplied. Single glazed sashes incorporate putty profile beading or left open to accept putty by others.Acoustic Glazing

MH Joinery has extensive experience in the field of sound attenuation. Further details are available upon request.Health and Safety

Frames calculated to exceed CDM recommended limits can be supplied de-sashed if required for ease of handling and fitting. A site commissioning service by our skilled remedial team is available. Please ask for further details.Security

Sections within the entire MH Joinery product range have externally beaded profiles in line with good joinery practice. Factory glazing incorporates a proven security tape and pinned glazing beads.The Woburn window has been tested to PAS24.

Fire exit and retardant designed frames

Fire resistant framing and minimum sized egress information is available on requestBuilding Regulation Part ‘L’

Thermal simulation testing has been carried out in accordance with ISO 15099. All products passed thermal conductivity readings in line with or exceeding Document Part 'L' and meet the latest regulation standards (October 2010).Window Energy Rating

MH Joinery manufacture a range of BSI A - C rated windows (WER). Our products meet or exceed the current Building Regulation requirements. Energy rating details are available upon request.Applied glazing bars

To meet the visual requirements of clients and planning authorities, MH Joinery has adopted the applied glazing bar system to replicate slim sectional bars of single glazed windows.A 22mm bar is standard with a 19mm option. Internal bars are tenon-jointed into the sash and external bars applied to the glass in a controlled environment as a matrix, in a putty-check design. Bars applied this way are extremely unlikely to delaminate away from the glass over time. The air space within the sealed unit is filled with a back-to-back spacer, to visually replicate individual panes.